No Iron and Steel in Construction of Ram Mandir: Tap to Know Why.

No Iron and Steel in Construction of Ram Mandir: Shri Nipendra Misra the chairperson of the construction committee says “The temple has been made to last a thousand years “

No Iron and Steel in Construction of Ram Mandir

As we all know the temple dedicated to Lord Ram is being made in Ayodhya and it marks one of the challenges to make the temple. The committee says that the temple is built keeping in mind the Historical beliefs of Hindus and structured just like the ancient temples. As Shree Nipendra Misra said this temple is made to last more than a thousand years, it says that the strength of the temple stands strong. He also said that the construction of this temple included scientists who contributed to this structure, even scientists from ISRO used their technologies to make this temple unique and beautiful.

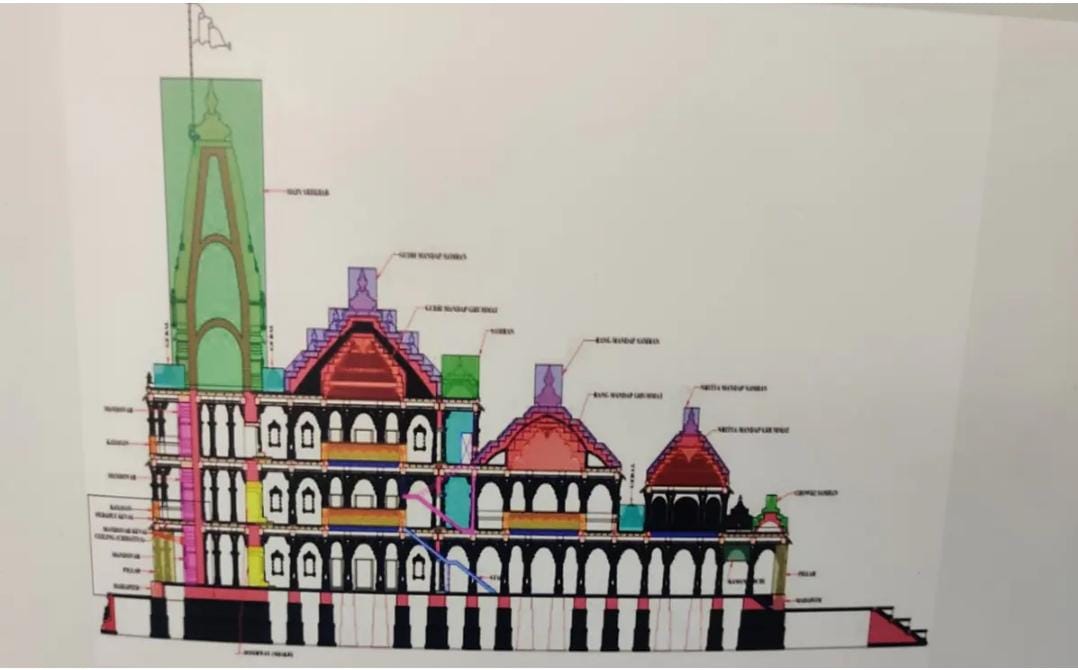

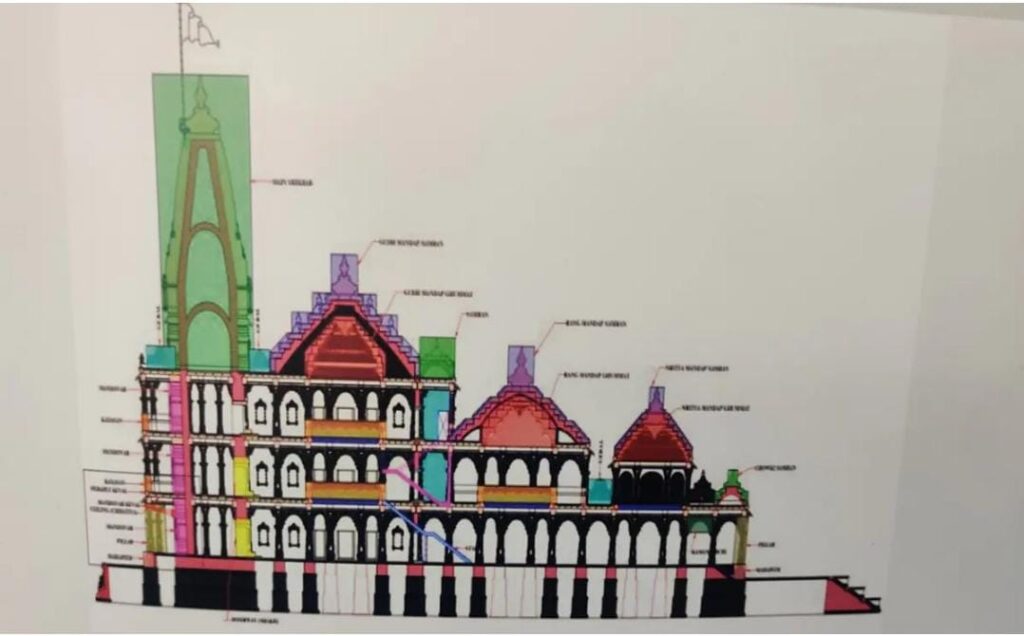

Architecture of the Temple

As per the sources, the temple is made following the Nagar Shaily which is a North Indian Temple Design done by Chandrakant Sompura whose family has been designing temples for the last 15 generations. They have built more than 100 temples to date.

“In the annals of architecture Shri Ram Temple will be the rarely seen, unique kind of splendid creation ever conceptualized not only in India but at any place on Earth,” says Mr. Chandrakant Sompura.

The total temple is 2.7 acres and the built-up area will be 57,000 sq. ft. This will be a three-storey building, says Nripendra Mishra. He says no iron or steel was used in the temple as the lifespan of steel is only 80-90 years. The height of the temple is about 161 feet high or about 70% of the height of the Qutab Minar.

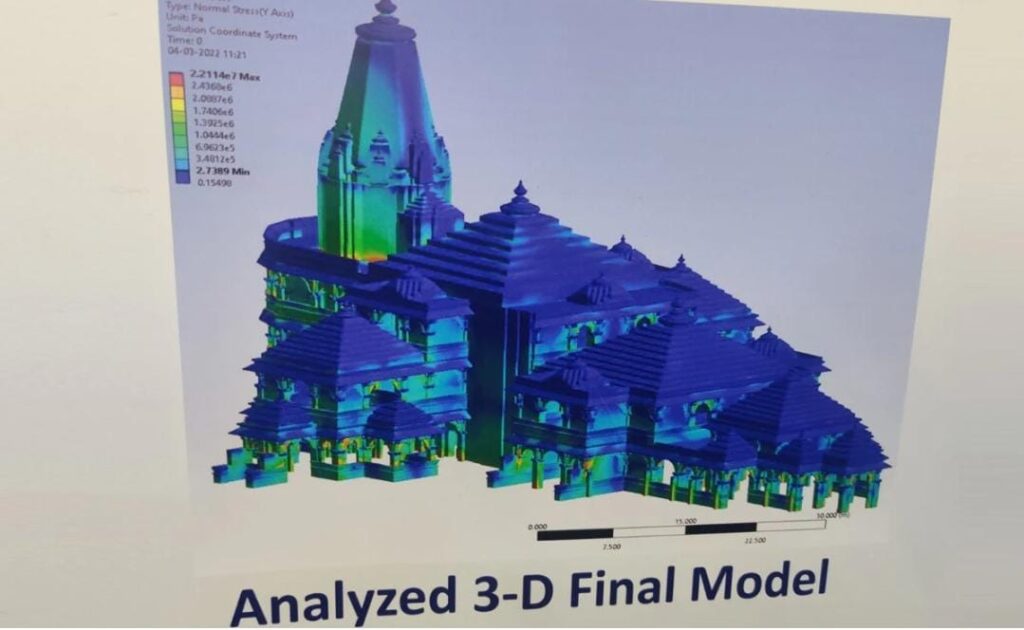

“Granite, sandstone, and marble of the highest quality are used and no cement or lime mortar is used in the joints, only locks and keys and timbers and timbers are used throughout the construction.” and Dr. Pradeep Kumar Ramancharla, director, a Central Building belongs to Research Institute, actively involved in the construction industry.”.CBRI claims that the structure of the 3-story buildings is designed to resist earthquake recurrence for 2500 years.

Challenging Era in the Making

Mr Misra says the survey revealed that the soil below the temple was sandy and unstable as the river Sarayu flowed close to the site at one point, this posed a particular challenge. But scientists have cleverly come up with solutions to this problem.

First, the entire temple was dug to a depth of 50 feet [15 m] “At this site, engineered soil was poured at a depth of 12-14 meters, no steel bonding was used, and the 47-layer foundation was built to make it as a solid rock ” says Ramancharla.

A 1.5 m thick layer of M-35 grade non-ferrous concrete was poured over this as reinforcement. To further strengthen the foundation, a 6.3-metre thick granite plinth mined from southern India was installed.

Usage of Rajasthani Sandstone

The part of the temple that visitors can see is the ‘Bansi Paharpur’ pink sandstone mined from Rajasthan. According to CBRI, the total number of columns on the ground floor is 160, on the first floor 132, and on the second floor 74, all made of sandstone and carved on the exterior The ornate sanctum is made of white marble quarried from Rajasthan. Incidentally, the Taj Mahal was made of diamonds from the Makrana mines.

“After analyzing 50 computer models, the selected prototype, which preserves Nagara style architecture, ensures functionality and architectural integrity. The proposed changes make the building’s architecture.” great while maintaining 2,500-year return period seismic safety, without steel reinforcement,” says CBRI.

Also Read: Man Behind Rashmika Mandanna’s Fake Video Arrested: Here’s the Details.

The organization has been involved in the construction of the Ram Temple since early 2020 and has given the following support to the project: construction of the main temple, the ‘Surya Tilak’ mechanism, Structural testing of the temple foundation, and structural health assessment of the main temple.

Sayings of the Archeologists

Dr. Sharada Srinivasan, an archaeologist specializing in heritage metals at the National Institute of Advanced Studies in Bangalore, says, “The traditional style of temple construction in ancient times was dry stone and basically, mortar or iron and steel was not used, (although its form in later.” periods such as in the 12th century Konarak temple the use of.” numerous structural iron beams is seen as well as iron does in some temples).

The mortise and tenon method of stone joining is traditionally used to hold blocks together i.e. with spaced grooves and pegs, and a tribute system of lintels spanning columns with horizontal beams was used to create a more pyramidal form. These aspects can also be seen in the great potential of the sandstone Rama temple, while the sandstone also has good tensile strength for the interstitial stones used to support the trabeate structure.”

Ramancharla asserts that “a temple may have heritage architecture as its foundation, but Ram Temple is defined by most of today’s finite resource analysis, most sophisticated software tools, and 21st-century building codes.”

“There can be no doubts that based on the current state of the art knowledge the Ram Mandir will surely survive more than a thousand years,” Ramancharla adds “It was a most enjoyable experience and great learning exercise as such challenges come maybe once in a lifetime.”

we hope you found this article helpful, for more such informative content stay tuned.

One Comment